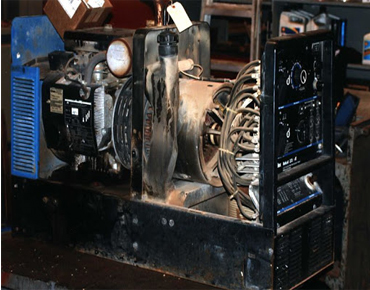

Welding Generators Repairing

Our Welding Generator Repairing Services are offered to fulfill the diverse requirements of fabrication and process industries. The generator is used to provide uninterrupted power supply while welding the structures and process equipments, hence, any kind of fault in it directly affects the manufacturing unit. Our highly experienced team comprises of skilled technicians and professionals who carry out this repairing work in adherence to the industry norms. We are specialized in repairing any model and capacity of welding generator.

We Servotech Pune are leading repairing of Welding Generators Repairing Services in Pune | Servotech Pune Maharashtra India.

Servotech Pune has been the leading service provider of Welding Generators repairing in Pune. We specialize in repairing and maintaining welding equipment. Our experienced team ensures quality service for generators ranging from 200AMP to 400AMP.

A welding generator is a portable device that combines a welding machine and a generator to provide both welding capabilities and electrical power on-site. Whether it is AC generators or welding machines trust us for efficient solutions to keep your equipment running smoothly.

Benefits of repairing welding generators

1. Cost Savings: Repairing a welding generator is often more cost-effective than replacing the entire unit. Identifying and fixing specific issues can be more economical than investing in a new machine.

2. Extended Equipment Lifespan: Regular repairs and maintenance can significantly extend the lifespan of a welding generator. Addressing issues promptly prevents further damage and ensures the equipment continues to function efficiently over the long term.

3. Minimized Downtime: Timely repairs reduce downtime by addressing problems before they escalate. This is crucial for industries and projects with tight schedules, ensuring continuous operation and productivity.

4. Enhanced Safety: Faulty welding generators can pose safety risks. Repairing and maintaining the equipment ensures that safety features are functioning correctly, reducing the likelihood of accidents and injuries.

5. Consistent Performance: Repairing and fine-tuning the welding generator ensures consistent and reliable performance. This is essential for achieving high-quality welds and meeting project specifications.

Welding Generator Repair

Repairing welding generators is crucial to ensure their optimal performance, addressing issues like faulty circuits or worn-out components. Timely repairs enhance equipment longevity, reliability, and safety, minimizing downtime and preventing costly replacements. The benefits of welding generator repairing include improved efficiency, reduced operational costs, and a consistent power supply for welding applications.

FAQ's

A: Inconsistent arc performance may result from issues like a damaged electrode, faulty wiring, or a malfunctioning voltage regulator. Our professional inspection can identify and address the specific problem.

A: Overheating may be due to issues such as a clogged cooling system or a malfunctioning fan. Regular maintenance, including cleaning and inspecting the cooling components, can help prevent overheating.

Services Details

Advantages:

- Ensures un-interrupted power supply

- Quick turnaround time

- Years of trouble free operation

- Use of genuine and certified spare parts

- Quality repairing services in emergency situations

The Welding Generators Repairing Services are provided in following industries:

- Solvent plants

- Material handling industry

- Machine tools industry

- Steel industry

- Forging industry

- Sugar industry

- Distillery industry