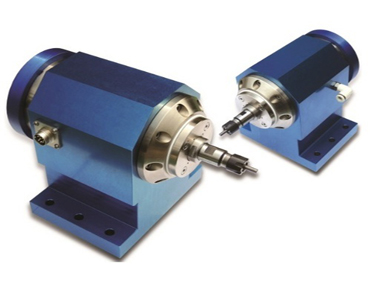

High Frequency Speed Spindle Repairing

We are highly specialized in rendering High Frequency Speed Spindle Motor Repairing Services with an excellent standard of quality. Our highly experienced team of technicians is well versed in serving all major brands of spindle motors like Fanuc, GE, Mitsubishi and others. In addition to this, we also use genuine OEM parts to ensure flawless functioning of motors.

Looking for reliable high frequency spindle motor repair in Pune? Servotech Pune serves as the best service provider of High Frequency speed spindle repairing in Pune! We specialize in repairing and maintaining spindle motors from major brands like Fanuc, Siemens, Yaskawa, and more.

Our highly experienced team ensures quality service for spindle motors of various capacities. We use genuine OEM parts to ensure flawless functioning. Count on us to maintain the smooth operation of your industrial gear.

Description

High-Frequency Speed Spindle Repairing involves the restoration and maintenance of high-speed spindles used in manufacturing processes. The need for repairing arises due to wear, malfunctions, or damage, ensuring optimal performance. Regular maintenance and repair contribute to uninterrupted operations, minimizing downtime and reducing overall expenses.

Advantages

- Increased efficiency

- Prolonged lifespan

- Cost-effectiveness, and

- Enhanced productivity

Why high frequency spindle repair is necessary?

1. Optimal Performance: Over time, high-frequency speed spindles can experience wear and tear, affecting their performance. Repairing helps restore and maintain the spindle's efficiency, ensuring it operates at its intended speed and precision.

2. Prevention of Downtime: Timely repairs prevent unexpected breakdowns and downtime in manufacturing processes. Proactive maintenance addresses potential issues before they escalate, contributing to continuous and reliable operation.

3. Cost-Effectiveness: Repairing a high-frequency speed spindle is often more cost-effective than replacing the entire unit. Regular maintenance and addressing issues promptly can extend the lifespan of the spindle and avoid costly replacements.

4. Enhanced Productivity: Repairs address any performance issues, allowing the spindle to function optimally and contribute to higher production output

FAQ's

A: It ensures prolonged spindle life, sustained performance, and prevents costly downtime in manufacturing processes.

Unusual noises, vibrations, decreased performance, or irregularities in machining quality may indicate the need for repair.

A: Regular preventive maintenance is recommended, with frequency depending on spindle usage and manufacturer guidelines to ensure optimal performance.

Services Details

Advantages:

- Well developed process control to ensure there are no bottlenecks

- Capable of carrying out in-hand repair tasks

- Fast and effective repairing work with the use of right genuine parts

- Reconditioned motors for the situations when the parts are hard to find

- A separate job number is assigned to provide accurate feedback

- No delay in the work due to constant monitoring

- 12 month warranty on workmanship on all repaired spindle motors

The High Frequency Speed Spindle Motor are used in following areas:

- Paper and particle board industry

- Material handling industry

- Machine tools industry

- Steel industry

- Forging industry

- Flour Mill

Technical specifications:

| Power Range | 00.08 KW TO 250 KW |

| Speed Range | Up to 150000 RPM |

| Frequency Range | Up to 2500 Hz |

| IP Class | IP54, IP 64 & IP 65. |

| Cooling Type | Oil cooling, water cooling, fan cooling, natural convection and independent axial ventilation |